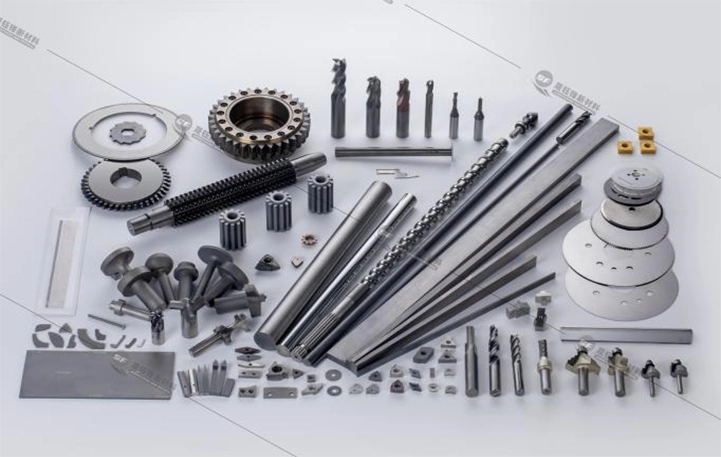

High-precision T-shaped milling cutter for efficient, durable, and accurate metal machining.

Cemented Carbide Cutter Tool series is a type of hard alloy material used for manufacturing cutting tools, which is widely used in various fields such as metal cutting, wood processing, plastic processing, etc. Materials are indispensable in modern metal processing and other material processing, providing important guarantees for improving processing efficiency, reducing production costs, and enhancing product quality.

The Cutter tool grades developed by Shengyufeng are fully reflected in the machining life of materials such as high-temperature alloys, stainless steel, and aluminum magnesium alloys in metal processing.

English

English  English

English