search Result Other

-

Classification of cemented carbide

10 27,2022

Hard alloy is one of the new materials developed by alloy new material manufacturers, which is mainly divided into three categories:1. Tungsten and cobalt cemented carbidesThe primary components are t...

Classification of cemented carbide

10 27,2022

Hard alloy is one of the new materials developed by alloy new material manufacturers, which is mainly divided into three categories:1. Tungsten and cobalt cemented carbidesThe primary components are t...

-

3C Electronics

Our precision-engineered tungsten carbide products meet the stringent demands of the 3C electronics industry, ensuring high performance and reliability.

3C Electronics

Our precision-engineered tungsten carbide products meet the stringent demands of the 3C electronics industry, ensuring high performance and reliability.

-

What are the powder metallurgy mold materials

10 27,2022

Powder metallurgy die materials can be roughly divided into two kinds of materials: strengthening materials and typical materials. The following are material characteristics and material applications....

What are the powder metallurgy mold materials

10 27,2022

Powder metallurgy die materials can be roughly divided into two kinds of materials: strengthening materials and typical materials. The following are material characteristics and material applications....

-

Medical Instruments

Our tungsten carbide materials are ideal for medical instruments, providing exceptional precision, durability, and biocompatibility.

Medical Instruments

Our tungsten carbide materials are ideal for medical instruments, providing exceptional precision, durability, and biocompatibility.

-

The basic situation of cemented carbide market in our country

10 27,2022

According to the data provided by the cemented Carbide Branch of China Tungsten Industry Association, in 2011, there were more than 300 cemented carbide production enterprises in China, with more than...

The basic situation of cemented carbide market in our country

10 27,2022

According to the data provided by the cemented Carbide Branch of China Tungsten Industry Association, in 2011, there were more than 300 cemented carbide production enterprises in China, with more than...

-

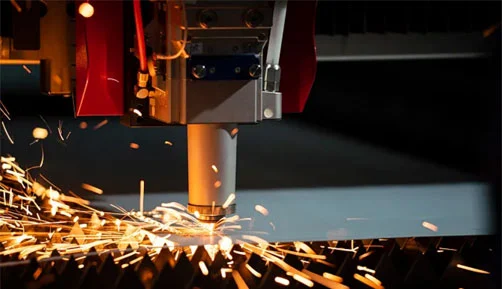

Cutting Tools

Our cutting tools made from tungsten carbide deliver unmatched sharpness and longevity, perfect for various industrial cutting applications.

Cutting Tools

Our cutting tools made from tungsten carbide deliver unmatched sharpness and longevity, perfect for various industrial cutting applications.

-

With the increase of energy saving and emission reduction requirements, powder metallurgy die process is widely used in metal products production

10 27,2022

At present, on average, the dosage of P/M mould products in each automobile only covers 5 ~ 6kg in our country. In view of energy saving and emission reduction, more enterprises will use P/M process t...

With the increase of energy saving and emission reduction requirements, powder metallurgy die process is widely used in metal products production

10 27,2022

At present, on average, the dosage of P/M mould products in each automobile only covers 5 ~ 6kg in our country. In view of energy saving and emission reduction, more enterprises will use P/M process t...

-

Geological and Mining Tools

Our tungsten carbide tools are designed for the toughest geological and mining conditions, offering excellent wear resistance and durability.

Geological and Mining Tools

Our tungsten carbide tools are designed for the toughest geological and mining conditions, offering excellent wear resistance and durability.

-

Metal magnetic core with the development prospect of The Times

10 27,2022

At present, there are four categories of soft magnetic materials widely used in the international science and technology industry: metal soft magnetic materials, ferrite magnetic ring, amorphous micro...

Metal magnetic core with the development prospect of The Times

10 27,2022

At present, there are four categories of soft magnetic materials widely used in the international science and technology industry: metal soft magnetic materials, ferrite magnetic ring, amorphous micro...

-

How to choose steel for hard alloy?

10 27,2022

The manufacturing cost of plastic mould is very high, and the material fee only accounts for a very small part of the cost of the mould. Therefore, the steel with good technology, stable performance a...

How to choose steel for hard alloy?

10 27,2022

The manufacturing cost of plastic mould is very high, and the material fee only accounts for a very small part of the cost of the mould. Therefore, the steel with good technology, stable performance a...

-

The following points should be paid attention to in the use of carbide punching needle

10 27,2022

Brief introduction: Hard alloy is a mixture of metal carbide powder and cobalt, commonly used metal carbide is tungsten carbide, titanium carbide, niobium carbide and vanadium carbide, they can make h...

The following points should be paid attention to in the use of carbide punching needle

10 27,2022

Brief introduction: Hard alloy is a mixture of metal carbide powder and cobalt, commonly used metal carbide is tungsten carbide, titanium carbide, niobium carbide and vanadium carbide, they can make h...

-

Introduction to powder metallurgy forming

10 27,2022

Die forming (die) is a widely used forming method in powder metallurgy production. Similar powder metallurgy processes were used in the second half of the 18th century and the first half of the 19th c...

Introduction to powder metallurgy forming

10 27,2022

Die forming (die) is a widely used forming method in powder metallurgy production. Similar powder metallurgy processes were used in the second half of the 18th century and the first half of the 19th c...

-

Introduction to powder pressing mold

10 27,2022

Because the powder pressing method is many, the powder pressing mold is also various. According to different pressing methods can be divided into: pressing die, finishing die, repressing die, forging ...

Introduction to powder pressing mold

10 27,2022

Because the powder pressing method is many, the powder pressing mold is also various. According to different pressing methods can be divided into: pressing die, finishing die, repressing die, forging ...

-

Introduction to tungsten steel round rod

10 27,2022

Tungsten steel round rod introduces the standard parts of die with larger output in China and the rapid development of die manufacturing technologyAt present, the standard parts of molds with large ou...

Introduction to tungsten steel round rod

10 27,2022

Tungsten steel round rod introduces the standard parts of die with larger output in China and the rapid development of die manufacturing technologyAt present, the standard parts of molds with large ou...

-

Tungsten steel (hard alloy) has high hardness

10 27,2022

Tungsten steel die (hard alloy) has high hardness, wear resistance, strength and toughness, good heat resistance, corrosion resistance and a series of excellent properties, especially its high hardnes...

Tungsten steel (hard alloy) has high hardness

10 27,2022

Tungsten steel die (hard alloy) has high hardness, wear resistance, strength and toughness, good heat resistance, corrosion resistance and a series of excellent properties, especially its high hardnes...

English

English  English

English